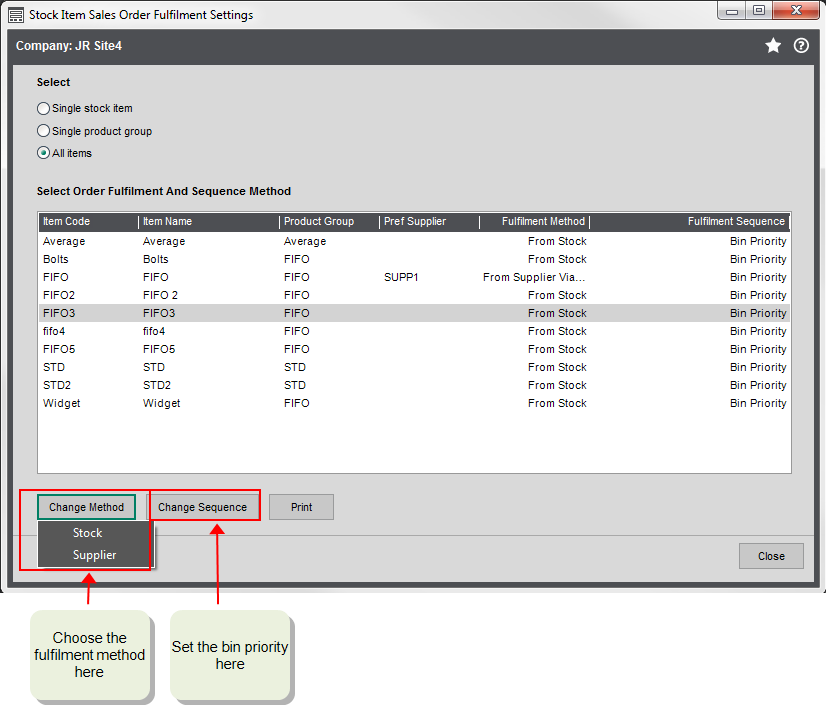

Your stock fulfilment methods help determine how your stock items are allocated to your sales orders. You can use two fulfilment methods in Sage 200:

-

From stock

This is the most commonly used method. Your stock items are allocated and despatched from the available stock in your warehouse(s). This is the default setting

-

From supplier via stock

This allows you to use back to back sales orders. When you add goods to a sales order, you can generate a purchase order for those items at the same time. When you receive the goods, they are automatically allocated to the sales order ready for despatch.

If you want to use this method, you must:

- Turn on the From supplier via stock method in the Stock Control Settings.

- Set a preferred supplier on the relevant stock items.

- Set the Supplier fulfilment method for the relevant stock items.

Choose how stock is allocated from your bins

If you store the same stock item in more than one bin in a warehouse, you can choose which bin the stock is allocated from first. This is useful if you want to make sure that your picking list allocates from the nearest bin, for example. You can set Sage 200 to allocate based on the following

- Bin priority - the stock is allocated based on the priority number set on the bin. Stock is allocated from the bin with priority 1 first and so on. This is the default setting.

- Smallest - Stock is allocated with the bin with the smallest quantity of free stock first.

- Largest - Stock is allocated from the bin with the largest quantity of free stock first.

What do you want to do?

Open: Settings > Stock Control > Stock Control Settings | Options

Open: Stock Control > Stock Records > Amend stock items Details | Supplier

Open: Stock Control > Stock Records > Amend stock items Details | Locations

Open: Stock Control > Stock Records > Stock Order Fulfilment